Papierherstellung

2010 haben unser Hauptproduzent und wir in 2 Dörfern mit der Aufforstung von Lokta angefangen. Hauptgrund war und ist unsere nachhaltige Versorgung mit Lokta. Außerdem möchten wir die nachhaltige Entwicklung Nepals unterstützen. Die ersten Pflanzen wurden in einer Baumschule in Kathmandu bestellt und von dort in die etwa 120 km weit entfernten Dörfer gebracht.

Die traditionellen Körbe, in denen die Pflanzen transportiert wurden, werden in Nepal hergestellt und dienen auch heute noch dem Transport von vielen unterschiedlichen Gütern. Wenn die Pflanzen erntereif sind, werden Äste abgeschlagen und entrindet. Die Rinden werden gewässert und dann geschlagen, um den Bast freizugeben, der für die Papierherstellung benötigt wird. Der Bast wird zerkleinert und Wasser hinzugefügt, so dass eine gleichmäßige, nicht zu wässrige Masse entsteht.

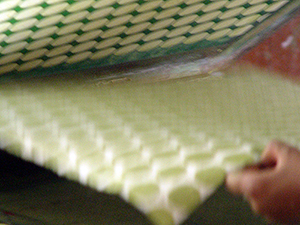

Ein Schöpfrahmen wird in ein Wasserbassin gehalten und je nach dem zu erzielenden Gewicht des Bogens wird eine entsprechende Menge Pulpe auf das Sieb geschüttet und gleichmäßig verteilt. Wenn die Pulpe gleichmäßig auf dem Sieb liegt, wird es aus dem Bassin gehoben, das Wasser fließt zurück ins Bassin. Der Rahmen wird aufgestellt und der Bogen trocknet in der Sonne.

Lokta-Recycling Bögen und auch die Bögen aus Baumwoll-Recycling-Pulpe (Indien) werden nicht stehend in der Sonne getrocknet; hier wird das Wasser aus den Bögen gepresst und dann werden sie zum Trocknen aufgehängt oder in Trockengestellen aufgehängt. Die Bögen werden in der Regel in den Dörfern an den Hängen des Himalaya hergestellt, wo die Loktapflanze wächst. Von dort kommen sie zu unseren Produzenten ins Kathmandu Tal. Hier werden sie sortiert, kontrolliert und kalandriert. Der Kalandrierungsprozeß ist sehr wichtig für eine feine und glatte Oberfläche des Papieres.

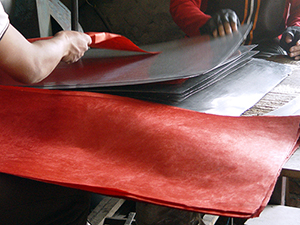

Danach können sie für die Produktion verwendet werden: sie werden gefärbt, im Siebdruck bedruckt, mit Wachs für Batikbögen behandelt… Für den Siebdruck gibt es in Nepal noch keine automatischen oder halbautomatischen Druckmaschinen; deshalb wird auf althergebrachte Weise das Sieb vorbereitet, und dann läuft alles per Hand und Auge: Das genaue Auge des Druckers und seine Fähigkeiten entscheiden über die Qualität des Druckes.

Die bedruckten Bögen trocken danach in Stapeln draußen, an der Sonne oder bei einigen Farben, die der Sonne nicht ausgesetzt werden sollten, auf der Leine im Raum. Von dort kommt das Papier dann in die Produktionsbereiche und wird dann in der Pack- und Kontrollabteilung nochmals kontrolliert, verpackt und an unser Lager geschickt. |                      |

Fotos der Produktion Anfang der 80er Jahre, bis heute hat sich nur wenig verändert.